Punching Process in Sheet Metal: A Core Technique Used by Metal Pressing Companies

By Shekhar Chaudhary 20-01-2026 1

The punching process in sheet metal is one of the most fundamental and widely used manufacturing techniques in modern industrial production. It allows the creation of holes and intricate cut-outs in metal sheets with precision, as well as dimensional accuracy, speed and repeatability. For advanced manufacturing firms such as Eigen Engineering, mastering the punching process in sheet metal is essential to delivering high-quality, cost-effective components across multiple industries.

Understanding the Punching Process in Sheet Metal

The punching process in sheet metal is a controlled cutting operation in which a defined portion of a metal sheet is removed by applying compressive force through a punch and die system. In this, the punch plunges into the metal sheet and presses it into a die cavity under it, leaving a cleanly cut pattern or shape.

Metal pressing companies rely on the punching process in sheet metal because it ensures repeatability, speed, and accuracy, making it suitable for both medium and large-scale production. The process is particularly successful to production of components that have standardized holes layouts and that have accurate geometries.

How Sheet Metal Is Formed Through Punching?

The punching process in sheet metal is a systematic and controlled operation designed to produce precise holes and cut-outs with high repeatability. That process has a set of steps and is done to guarantee the accuracy of dimensions, the safety of tools and repeatability of the output.

Step 1: Material Selection and Preparation

It starts by picking the right sheet metal material according to the requirements needed. Popular materials are stainless steel, mild steel, aluminium, copper and brass.

Prior to processing, the metal sheet is examined for surface defects, consistency in thickness, and flatness. Proper material preparation is essential for achieving accurate results during the punching process in sheet metal.

Step 2: Tooling Selection and Setup

During this process, the appropriate punches and dies should be used depending on the size of the hole needed, the shape, and the tolerance. The motion tooling is fixed to the press machine.

Metal pressing companies ensure precise alignment between the punch and die to prevent tool wear, misalignment, or defective punching outcomes.

Step 3: Sheet Positioning and Clamping

The sheet metal goes in the press bed and is pressurised at the correct location using guide or CNC-controlled positioning machines. It is then firmly clamped so that it does not move when punching.

Correct positioning is critical to maintain repeatability throughout the punching process in sheet metal.

Step 4: Application of Punching Force

When the setup has been reached, the press machine is turned on. The punch strikes the sheet metal surface downwards with measured force.

With an increase in pressure, the deformation of the metal is first elastic and then plastic. The sliding action ultimately surpasses the shear strength of the material, and fracture starts along the punch line.

Step 5: Shearing and Material Separation

The punch completely cuts through the sheet metal and gets into the die cavity. The required hole or cut-out is shaped, and the material taken away is the slug that detaches itself from the piece.

The die bears the surrounding metal, and therefore, it provides clean edges, and unwanted distortion will be avoided.

Step 6: Punch Retraction and Ejection

Once the cut is done, the punch goes into its original position. The slug is pushed down the die opening in a collection system or scrap container to be recycled.

This step allows the press to prepare for the next stroke in the punching process in sheet metal.

Step 7: Repetition of Punching Operations

Depending upon the programmed pattern or tooling layout, more holes or features will be punched as part of the constant punching cycle. Modern punch presses used by metal pressing companies can perform multiple strokes per minute, enabling high-volume production.

Step 8: Burr Formation and Edge Inspection

The shearing of the punched hole may result in the formation of a small burr along the exit side of the punched hole. The punched part is checked to verify the dimensional accuracy, quality of holes and surface integrity.

Step 9: Secondary Finishing Operations

Secondary operations, e.g. deburring operations, surface finishing operations, or cleaning, are performed in case it is necessary to remove sharp edges and enhance the quality of the components.

These finishing steps enhance the functional and aesthetic properties of parts produced through the punching process in sheet metal.

Step 10: Final Quality Check and Dispatch

Final quality inspection is done on the completed components to determine whether they meet design specifications or not. The parts that have been approved are finally packaged and sent out, or continue with the assembly processes.

Benefits of the Punching Process in Sheet Metal

The punching process in sheet metal offers several operational and economic advantages:

- Privately manufactured cost-effective hole production (mid-size and high-volume production).

- Good repeatability by operating at high speeds.

- Ability to make holes of different shapes and sizes.

- minimised the secondary forming or machining operations.

- Widely compatible and tolerant.

For metal pressing companies such as Eigen Engineering, these benefits translate into improved productivity and consistent quality.

Tools and Equipment Used in Sheet Metal Punching

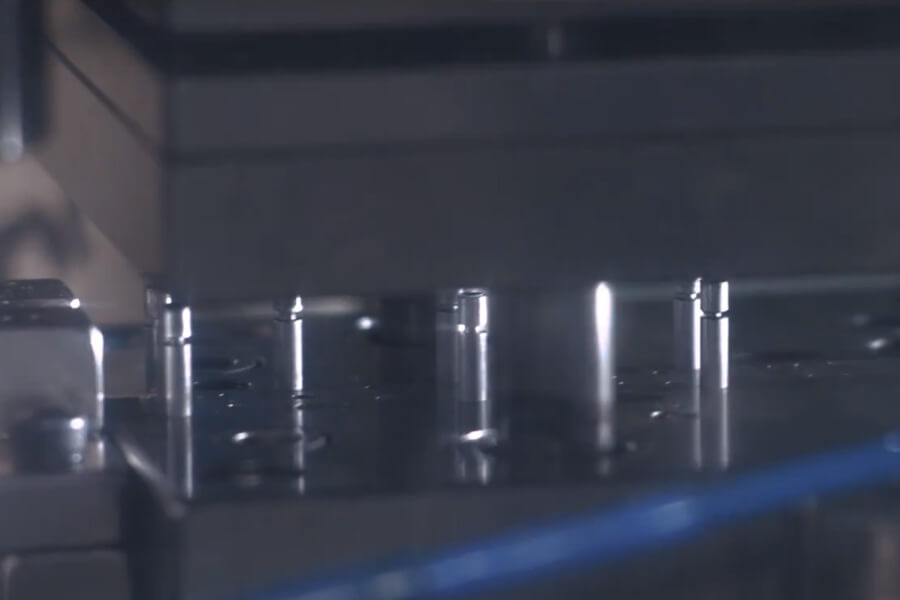

The successful implementation of the punching process in sheet metal depends on selecting the appropriate tools and equipment. The mentioned machines consist mainly of mechanical or hydraulic press machines that produce the necessary punching load. These machines have a ram where the punch is kept, and controlled pressure is provided by it.

Depending on the material thickness, size of holes, and complexity of the design, tooling selection depends on these factors. Dies, punches, and specialised tooling can be customised to meet specific production requirements, allowing metal pressing companies to adapt to varied client specifications.

Common Punching Techniques Used by Metal Pressing Companies

Punching methods used are also varied based on the use:

- Piercing: Creates holes without removing material entirely, commonly used for fastener placements.

- Notching: Removes small sections from the edge of the sheet to form tabs or features.

- Slootting: Produces elongated grooves for wiring, plumbing, or alignment purposes.

- Nibbling: Involves a series of small overlapping punches to create complex contours and customised shapes.

These techniques highlight the versatility of the punching process in sheet metal.

Material Compatibility and Quality Considerations

Advancements in tooling and press technology allow the punching process in sheet metal to be applied to materials such as stainless steel, aluminium, copper, brass, iron, and special alloys. Quality is influenced by parameters including punch geometry, applied force, material thickness, and tool condition.

Adhering to established design guidelines (such as maintaining minimum hole diameters relative to material thickness) ensures optimal performance and extended tool life.

In Conclusion, the punching process in sheet metal remains a cornerstone manufacturing technique for precision fabrication. Its speed, accuracy, and adaptability make it indispensable for metal pressing companies seeking reliable and scalable production solutions. At Eigen Engineering, this process is executed with advanced machinery, robust tooling, and strict quality control to meet demanding industrial standards. Through efficient sheet metal punching, Eigen Engineering continues to deliver high-performance components tailored to diverse engineering applications.