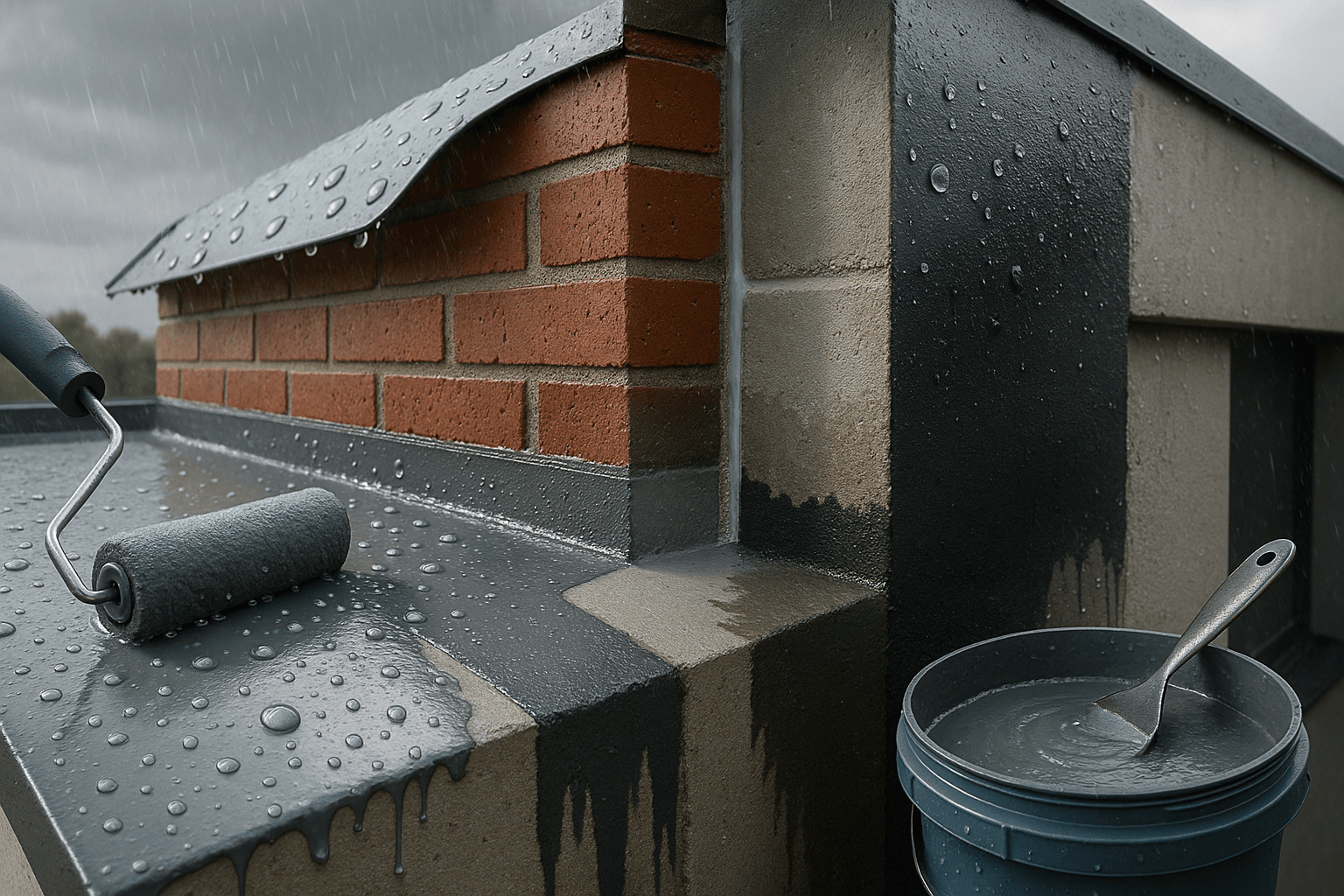

In Pakistan, where monsoon rains drench Punjab’s plains, humid coastal winds batter Karachi, and arid heat tests Balochistan’s structures, waterproofing is the key to building resilience. Construction chemicals designed for waterproofing transform vulnerable surfaces into impenetrable barriers, safeguarding homes, bridges, and commercial buildings from moisture damage. From acrylic coatings to silicone sealants, these compounds ensure structures stand strong against Pakistan’s diverse and challenging climate. Partnering with a reliable textile chemical supplier—often a source for versatile chemicals used across industries—provides access to solutions tailored for local conditions, blending durability with practicality. This isn’t just about sealing cracks—it’s about fortifying Pakistan’s buildings to thrive in rain, humidity, and heat with unmatched strength and longevity.

What Are Waterproofing Construction Chemicals?

Waterproofing chemicals are specialized compounds that protect building materials from moisture, tailored for Pakistan’s humid and monsoon-prone regions. These products, available as liquids, powders, or membranes, ensure structural integrity in diverse climates.

- Composition Breakdown Details: Formulated from acrylic polymers, silicones, or epoxy resins, designed for robust moisture resistance and durability.

- Core Functionality Overview: Create water-repellent barriers, strengthen surfaces, or seal joints, ensuring leak-free performance consistently.

- Application Scope Specificity: Used in coatings, sealants, or admixtures for roofs, basements, or infrastructure projects extensively.

- Local Climate Compatibility Advantage: Tailored by Pakistan suppliers for humid, rainy, or arid conditions, ensuring reliable protection.

- Efficiency Impact Metrics: Applied in small doses (0.1-5% of material weight), delivering substantial waterproofing benefits effectively.

Waterproofing chemicals shield Pakistan’s buildings, weaving resilience into every structure with precision and strength.

How Do Acrylic Waterproofing Agents Protect Roofs?

Acrylic waterproofing agents are popular for creating flexible, durable coatings that shield roofs from Pakistan’s heavy rainfall and humidity.

- Water-Repellent Film Formation: Form a seamless, elastic layer, preventing leaks on flat or sloped roofs in urban Karachi.

- UV Resistance Capability Included: Protect against sun damage, preserving roof integrity in sunny regions like Tharparkar consistently.

- Crack-Bridging Technology Applied: Stretch over minor cracks, ensuring watertight surfaces in monsoon-prone Punjab effectively.

- Application Ease Advantage Provided: Brush or spray easily, reducing labor time on residential or commercial roofs significantly.

- Supplier Customization Options Available: Pakistan suppliers offer acrylics tailored for local roofing materials and climate challenges.

Why Are Silicone Sealants Ideal for Joints?

Silicone sealants are essential for sealing gaps and joints, ensuring watertight buildings in Pakistan’s humid and rainy climates.

- Flexible Sealing Mechanism Employed: Provide elastic seals for expansion joints, accommodating movement in bridges or high-rises reliably.

- Moisture Resistance Feature Integrated: Prevent water ingress, ideal for humid coastal areas like Gwadar consistently.

- Temperature Stability Advantage Offered: Withstand heat or cold, ensuring durability in northern Pakistan’s variable climates effectively.

- Simple Application Process Provided: Applied with caulking guns, streamlining installation on construction sites efficiently.

- Supplier Tailored Formulations Available: Pakistan suppliers provide sealants suited for local materials and environmental conditions.

How Does Epoxy Resin Bolster Waterproofing?

Epoxy resin is a powerhouse for waterproofing, offering robust coatings and adhesives for Pakistan’s buildings and infrastructure projects. Known for its strength, epoxy resin in Pakistan forms a glossy, impermeable layer that protects basements, water tanks, and industrial floors from moisture. It resists chemical spills, making it ideal for factories in Sialkot, and its durability withstands heavy wear in commercial spaces like Lahore’s malls. UV-resistant variants prevent fading in sunny regions, while anti-slip formulations enhance safety in wet areas. Local suppliers offer epoxy resins tailored for Pakistan’s climate, ensuring long-lasting, leak-free performance across diverse construction needs.

How Do Polyurethane Coatings Resist Moisture?

Polyurethane coatings are versatile waterproofing chemicals that protect surfaces from moisture and wear in Pakistan’s challenging climates.

- Waterproof Barrier Creation Mechanism: Form a tough, flexible coating, ideal for roofs or terraces in rainy Punjab consistently.

- Abrasion Resistance Feature Included: Shield surfaces from wear, perfect for high-traffic floors in Karachi’s commercial spaces.

- Chemical Resistance Advantage Provided: Protect against spills, suitable for industrial plants or warehouses in Faisalabad effectively.

- Seamless Application Process Offered: Apply via brushing or spraying, ensuring even coverage on complex surfaces efficiently.

- Supplier Specialized Solutions Available: Pakistan suppliers provide polyurethanes tailored for local construction and climate needs.

Are Waterproofing Chemicals Safe for Use?

Safety is a priority, and modern waterproofing chemicals are designed to protect workers, residents, and the environment in Pakistan’s construction projects.

- Low-Toxicity Formulations Ensured: Meet global safety standards, minimizing skin or respiratory risks during application or curing safely.

- Clear Safety Guidelines Provided: Suppliers offer detailed data sheets, recommending gloves, masks, and ventilation for safe handling.

- Residue-Free Curing Process Achieved: Leave no harmful traces, ensuring safety for homes, offices, or public buildings consistently.

- Regulatory Compliance Standards Upheld: Align with international regulations, supporting Pakistan’s construction export market requirements.

- Eco-Friendly Options Available Offered: Include biodegradable or low-VOC chemicals, reducing environmental impact significantly.

How Do Waterproofing Chemicals Support Sustainability?

Sustainability is reshaping Pakistan’s construction industry, and waterproofing chemicals contribute to eco-friendly building practices effectively.

- Water Conservation Benefits Achieved: Low-water formulations reduce resource use in mixing or application, saving resources sustainably.

- Durable Finish Longevity Ensured: Extend structure lifespan, reducing repair or replacement needs in Pakistan’s urban centers.

- Energy-Saving Application Methods Applied: Fast-curing chemicals lower energy consumption during construction processes efficiently.

- Biodegradable Variants Offered Provided: Break down naturally, minimizing environmental pollution in construction waste streams.

- Green Supplier Initiatives Supported: Pakistan’s chemical industries offer eco-conscious solutions for global sustainability standards.

Waterproofing chemicals weave sustainability into Pakistan’s buildings, crafting a resilient, eco-friendly future.

Why Are Waterproofing Chemicals Cost-Effective?

Waterproofing chemicals deliver robust performance at low costs, benefiting Pakistan’s builders and contractors significantly.

- Low-Dosage Efficiency Feature Ensured: Small amounts (0.1-5%) achieve notable results, reducing material expenses for projects.

- Construction Time Savings Advantage: Quick application or curing cuts labor and equipment costs on sites efficiently.

- Maintenance Cost Benefits Provided: Durable coatings reduce repair expenses, saving money for building owners long-term.

- Bulk Packaging Availability Offered: Supplied in 20-200 kg kits, lowering per-unit costs for large-scale construction.

- Affordable Local Pricing Structure: Pakistan suppliers offer competitive rates, minimizing import expenses for contractors.

How Are Waterproofing Chemicals Applied in Construction?

Applying waterproofing chemicals requires precision to maximize their benefits in Pakistan’s construction projects. Using epoxy resin in Pakistan, along with other compounds, ensures robust, leak-free structures when sourced from reliable suppliers. These chemicals are applied via brushing, spraying, or rolling for coatings, or mixed into concrete as admixtures for uniform protection. Used in precise ratios (0.1-5% of material weight), they deliver cost-effective results without waste. Compatible with local cement and aggregates, they integrate seamlessly, and standard equipment handles their application, minimizing costs. Local suppliers provide technical support to optimize application techniques, ensuring consistent, durable outcomes for buildings.

What Challenges Come with Waterproofing Chemicals?

While waterproofing chemicals offer benefits, they require careful management to achieve optimal results in Pakistan’s construction industry.

- Application Accuracy Requirements Needed: Incorrect ratios can affect performance, needing skilled workers and precise measurement techniques.

- Storage Condition Needs Specified: Must be stored in cool, dry environments to maintain stability in humid climates like Karachi.

- Surface Preparation Necessity Emphasized: Surfaces need cleaning for proper adhesion, ensuring effective waterproofing consistently.

- Upfront Cost Considerations Involved: Initial expenses may be higher, though long-term savings offset costs significantly.

- Worker Training Requirements Essential: Staff need training to handle and apply chemicals safely and effectively consistently.

What’s the Future of Waterproofing Chemicals in Pakistan?

The future of waterproofing chemicals in Pakistan is promising, driven by innovation and growing infrastructure demands across urban and rural areas.

- Smart Material Developments Emerging: Self-healing chemicals repair cracks, ideal for seismic zones or high-rise structures effectively.

- Eco-Friendly Advances Progressing: Bio-based compounds reduce petroleum use, supporting sustainable construction practices consistently.

- Market Expansion Drive Growing: Pakistan’s construction growth fuels demand for advanced waterproofing solutions rapidly.

- Automated Application Innovations Advancing: Stable formulations support automated coating, boosting project efficiency significantly.

- Global Competitiveness Strengthened: Innovative chemicals position Pakistan as a leader in international construction markets.

Waterproofing chemicals are building a future where Pakistan’s structures stand strong against any storm.

Comparison Table of Waterproofing Chemicals

Chemical | Function | Key Properties | Applications | Packaging | Price (PKR/kg) |

| Acrylic Waterproofing | Water resistance | Flexible, one-component coating | Roofs, basements, terraces | 20 kg pails | 800-1,000 |

| Silicone Sealant | Joint sealing | Elastic, weather-resistant seal | Expansion joints, cracks | 20 kg pails | 900-1,200 |

| Epoxy Resin | Protective coating | High chemical resistance, glossy finish | Basements, water tanks, floors | 20 kg kits | 1,000-1,300 |

| Polyurethane Coating | Water resistance | Tough, flexible, UV-resistant layer | Terraces, industrial floors | 20 kg pails | 1,100-1,400 |

| Bitumen Emulsion | Waterproof coating | High adhesion, durable film | Foundations, underground structures | 200 kg drums | 600-800 |

FAQs About Waterproofing Chemicals

What are the best waterproofing chemicals for Pakistan?

Acrylics, silicones, epoxy resins, and polyurethanes protect buildings from moisture effectively.

How do acrylic agents waterproof roofs?

They form a flexible, water-repellent layer, preventing leaks on flat or sloped roofs.

Are waterproofing chemicals safe for workers?

Yes, they meet global standards, minimizing risks when handled with proper safety measures.

Can silicone sealants prevent building leaks?

Yes, they seal joints and cracks, ensuring watertight structures in humid climates.

How do waterproofing chemicals promote sustainability?

They reduce water and energy use, include biodegradable options, and extend structure life.

Where can I source waterproofing chemicals in Pakistan?

Suppliers in Karachi, Lahore, and Faisalabad offer reliable chemicals with technical support.

What’s the shelf life of waterproofing chemicals?

Typically 12-24 months when stored in cool, dry conditions, per supplier guidelines.

Do waterproofing chemicals reduce construction costs?

Yes, low dosages and durable coatings lower material and maintenance expenses effectively.

Are waterproofing chemicals suited for Pakistan’s climate?

Yes, they resist moisture, UV, and temperature changes, ideal for diverse conditions.

How are waterproofing chemicals applied to buildings?

They’re applied via brushing, spraying, or mixing into concrete for seamless protection.

Wrapping Up

Waterproofing chemicals, from acrylics to epoxy resins, are revolutionizing Pakistan’s construction industry by delivering leak-free, durable buildings. These compounds meet the needs of homes, bridges, and commercial projects while promoting sustainability and cost savings in challenging climates. By partnering with reliable suppliers, builders gain access to customized solutions, expert guidance, and affordable pricing tailored for Pakistan’s unique conditions. Ready to fortify your structures against rain and humidity? Connect with a trusted supplier today and build buildings that stand strong and dry for generations!