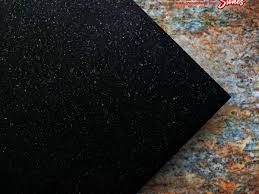

Absolute black granite has earned a serious reputation in the stone world. Designers love it. Builders trust it. Homeowners keep asking for it again and again. On the surface it looks simple just a deep black stone with a clean finish. But behind that smooth polished slab there is a long chain of effort, investment and decision making that shapes its final price. Many buyers only see the cost per square foot, not the real story behind it.

This article breaks down the true cost factors behind absolute black granite supply in a way that actually makes sense. No fluff, no overdone technical talk. Just real insight written for people who want to understand what they are paying for and why it matters.

Where absolute black granite really comes from

Absolute black granite is mainly sourced from specific regions in India. The geology of these areas is unique and not every quarry produces the same shade or density. Even within the same region, two quarries can give very different quality blocks. This alone creates a big difference in cost.

Quarry owners invest heavily before a single block is removed. Land leases, government approvals, environmental compliance and safety systems cost serious money. Sometimes a quarry sits idle for months due to permits or weather issues, yet expenses keep running. All of this gets factored into the base price of the stone, even if buyers never see it.

Another thing most people dont realize is that true absolute black is rare. Many stones look black but under sunlight or polishing they show grey tones or lighter minerals. Blocks that meet the strict absolute black standard are fewer, which naturally raises their value.

Extraction is not as simple as cutting stone

Removing a massive granite block from the earth is skilled work. It is not about speed, it is about precision. One wrong cut and the block cracks, losing thousands of dollars instantly. Quarrying requires advanced machinery, trained workers and constant maintenance.

Fuel costs alone are massive. Heavy equipment runs daily and fuel prices dont stay stable. Add labor wages, safety gear, machine parts and repair work, and the cost of extraction keeps climbing. These are not optional expenses. They are essential for consistent supply.

Weather also plays a role. During heavy rains or extreme heat, quarry operations slow down or stop. That means lower output but fixed costs remain the same. When supply tightens, prices adjust to cover the gap.

Block quality decides slab yield

Not every granite block produces the same number of usable slabs. Some blocks have hidden fractures or mineral lines that only show up during cutting. When that happens, a large portion of the block may go to waste.

High grade blocks with uniform color and structure produce more sellable slabs. These blocks are more expensive to begin with because quarry owners know their value. Lower grade blocks cost less but yield less and need more processing to meet standards.

This is why experienced buyers prefer working with a reliable absolute black granite slabs supplier, granite slabs exporter and supplier who understands block selection deeply. The right supplier knows how to balance cost and yield without compromising the final look.

Processing adds another layer of cost

Once blocks reach the processing unit, the real transformation begins. Cutting a block into slabs requires multi wire saw machines that cost millions. These machines need skilled operators and constant calibration.

After cutting, slabs go through polishing. Polishing absolute black granite is not easy. The surface needs to be flawless because even tiny imperfections show clearly on black stone. Achieving that mirror finish takes time, abrasives, water and energy.

Water usage is another hidden cost. Granite processing consumes huge amounts of water for cooling and polishing. Many factories invest in water recycling systems to meet environmental rules. These systems are expensive to install and maintain but unavoidable.

Electricity costs also matter. Processing plants run heavy machines for long hours. Power rates directly affect production cost, and in many regions power is not cheap or reliable.

Labor skill is a big price driver

Absolute black granite demands skilled hands. From machine operators to quality inspectors, trained labor is essential. Unskilled work leads to wastage, uneven polishing and rejected slabs.

Wages have risen over the years, especially for experienced workers. Retaining skilled staff requires fair pay, safe working conditions and benefits. These costs reflect in the final slab price, even if buyers dont think about it.

Factories that cut corners on labor may offer cheaper prices, but quality issues often show up later. That is why long term buyers usually stick with trusted granite slabs exporter and supplier partners instead of chasing the lowest quote.

Quality control is strict for a reason

Absolute black granite is unforgiving. Any inconsistency in color, thickness or finish stands out immediately. That is why serious suppliers invest heavily in quality control.

Each slab is inspected under proper lighting. Thickness is measured, surface is checked for pinholes, waves or shade variation. Slabs that dont meet standards are downgraded or rejected.

This process takes time and manpower. Rejected slabs mean loss, but shipping poor quality stone causes bigger losses in reputation and returns. Responsible suppliers absorb these costs to protect long term business.

Packaging and handling are not cheap

Black granite slabs are heavy and fragile at the same time. Improper handling leads to breakage, especially during transport. To prevent this, slabs are packed using strong wooden crates, foam, plastic sheets and steel strapping.

Wood prices fluctuate and export grade packaging must meet international standards. Fumigation, heat treatment and certification add to the cost. Even nails, bolts and labor for packing are part of the final price, though buyers rarely notice.

Handling equipment like cranes and forklifts also require maintenance and trained operators. Every movement of a slab has a cost attached to it.

Transportation shapes the final price

Moving granite from quarry to factory, then to port, and finally across oceans is expensive. Fuel prices, tolls, port charges and shipping rates all influence cost.

Ocean freight rates change often due to global trade conditions. Sometimes shipping alone can cost more than the stone itself. Delays at ports, container shortages or customs inspections can add unexpected expenses.

A professional absolute black granite slabs supplier, granite slabs exporter and supplier plans logistics carefully to minimize risks. Still, some costs are beyond control and must be adjusted in pricing.

Market demand and global competition

Absolute black granite is in demand worldwide. When large projects in the US, Europe or Middle East pick up, demand spikes. Limited supply combined with high demand pushes prices up.

Competition also plays a role. New materials and engineered stones compete with natural granite. To stay relevant, granite suppliers invest in better finishes, consistent sizing and faster delivery. These improvements cost money but help maintain market position.

Currency exchange rates affect exporters too. A small shift in exchange value can impact profit margins significantly. To stay stable, exporters often build a buffer into pricing.

Why the cheapest option is rarely the best

It is tempting to choose the lowest priced absolute black granite slab. But cheap stone often comes with hidden issues like color inconsistency, poor polishing or thickness variation.

Fixing these problems on site costs more than paying a fair price upfront. Delays, rework and customer dissatisfaction hurt projects badly. That is why experienced buyers focus on value, not just price.

A dependable granite slabs exporter and supplier offers transparency, consistent quality and after sales support. That reliability has a cost, but it saves money and stress in the long run.

Understanding cost builds better decisions

Knowing the real cost factors behind absolute black granite supply helps buyers make smarter choices. This stone is not just a commodity, it is a product shaped by geology, skill, investment and time.

When you see a well polished absolute black slab installed perfectly, you are looking at the result of many hands and many decisions. The price reflects that journey, even if it is not obvious at first glance.

For architects, builders and distributors, understanding this process creates respect for quality suppliers and realistic expectations on pricing. And honestly, that understanding makes every project smoother and more successful.

Tags : .....