Serial Device Server and Industrial Gateway – Bridging the Industrial Communication Gap

By smith roy 23-10-2025 26

In today’s fast-paced digital transformation era, seamless communication between machines, sensors, and control systems has become the backbone of efficient industrial operations. From manufacturing plants to power grids and logistics hubs, industries depend on uninterrupted data flow to monitor processes, optimise performance, and ensure reliability.

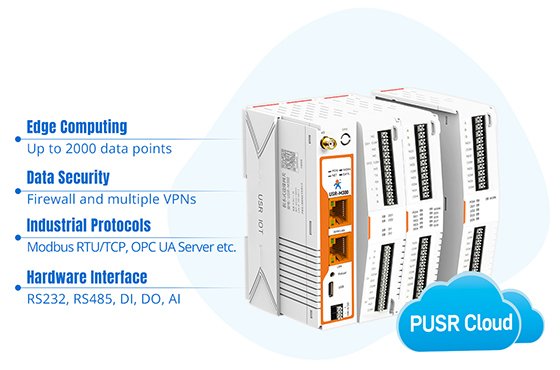

To connect traditional serial-based devices with modern network infrastructures, serial device server and industrial gateways play a crucial role. These technologies allow older equipment to integrate with modern digital systems, creating a bridge between legacy machinery and Industry 4.0 without the need for costly replacements.

What Is a Serial Device Server?

A serial device server is a networking unit designed to convert legacy serial communication protocols—such as RS-232, RS-422, and RS-485—into Ethernet or TCP/IP formats. This conversion enables older industrial devices to communicate across modern IP-based networks.

Many industrial devices, including barcode scanners, PLCs (Programmable Logic Controllers), and sensors, still depend on serial communication. Meanwhile, Ethernet has become the industry standard due to its scalability, speed, and reliability. By deploying a serial device server, organisations can connect legacy devices to Ethernet networks, facilitating remote monitoring, diagnostics, and control without replacing the existing system.

For instance, a PLC communicating via RS-485 can be connected to a central control system through a serial device server, allowing engineers to access and manage equipment remotely across the network.

What Is an Industrial Gateway?

An industrial gateway takes this concept a step further. It acts as a bridge between industrial control systems and IT or cloud environments. These gateways manage multiple communication protocols and provide data aggregation, protocol conversion, and secure transmission between diverse systems.

Industrial gateways are particularly beneficial in environments where multiple communication standards—such as Modbus, Profibus, CAN bus, or proprietary industrial protocols—coexist. They connect these systems to SCADA, ERP, or IoT platforms, enabling seamless data exchange between operational and enterprise networks.

By consolidating and converting data from various sources, industrial gateways enable real-time analytics, predictive maintenance, and remote monitoring, helping industries enhance productivity while reducing downtime.

How Do They Work?

Both devices act as translators and intermediaries between incompatible systems.

Serial Device Server Workflow

- Collects data from serial interfaces (RS-232, RS-422, RS-485).

- Converts serial data into Ethernet packets (TCP/IP or UDP).

- Sends data to servers, control systems, or cloud platforms.

- Enables network-based configuration and monitoring of connected devices.

Industrial Gateway Workflow

- Aggregates data from devices using multiple communication protocols.

- Converts and reformats data for compatibility with IT or cloud systems.

- Provides encryption, data filtering, and secure communication.

- Allows remote access, integration, and centralised management.

Applications Across Industries

1. Factory Automation

Serial device servers enable legacy machines to connect with Ethernet networks, allowing seamless automation.integrate these systems with SCADA or ERP software, ensuring real-time monitoring and data-driven decision-making.

Learn more about smart industrial automation at TechAutomationHub.

2. Energy and Utilities

Power stations and energy networks use various sensors and control devices. Industrial gateways collect and analyse parameters such as voltage and frequency, ensuring stable operations and supporting predictive maintenance.

3. Transportation and Logistics

Devices like ticketing systems, GPS trackers, and environmental sensors often rely on serial communication. With serial device servers, logistics companies can streamline fleet management, route optimisation, and maintenance planning.

4. Healthcare and Laboratories

Medical devices like patient monitors and analytical instruments typically use serial communication. A serial device server connects these tools to hospital networks, allowing quick access to critical data for diagnostics and analysis.

5. Retail and POS Systems

Point-of-sale (POS) systems, receipt printers, and barcode scanners frequently use serial communication. By connecting these devices through a serial server, retailers can centralise operations, track performance, and enhance customer service.

Key Benefits

✔ Cost Efficiency

Extends the lifespan of existing equipment, reducing the need for expensive upgrades.

Minimises downtime and maintenance costs.

✔ Remote Access and Management

Enables remote control, monitoring, and firmware updates.

Simplifies maintenance and reduces on-site intervention.

✔ Enhanced Security

Industrial gateways offer robust encryption, firewalls, and user authentication to protect networks from cyber threats.

✔ Scalability and Flexibility

Easily integrates new devices or systems without major infrastructure changes.

Supports IoT and cloud-based applications for future growth.

✔ Data Integration and Insights

Aggregates data from multiple sources for centralised analysis and smarter decision-making.

Choosing the Right Device

When selecting a serial device server or industrial gateway, consider:

- Protocol Support: Ensure compatibility with existing communication standards.

- Port Configuration: Select models with adequate serial and Ethernet ports.

- Data Speed: Verify compatibility with your network bandwidth.

- Security: Look for devices offering encryption, VPN, and firewall options.

- Remote Configuration: Choose units supporting remote updates and monitoring.

- Durability: Industrial-grade devices should withstand heat, vibration, and harsh conditions.

The Future of Industrial Connectivity

As industries move towards Industry 4.0 and the Industrial Internet of Things (IIoT), serial device servers and industrial gateways will remain central to digital integration. They help businesses modernise operations while preserving existing assets.

Emerging technologies like AI-driven analytics, edge computing, and cloud integration will rely heavily on these devices to enable smart factories, autonomous operations, and predictive systems.

For more insights on industrial networking and IoT innovations, visit IndustrialTechInsights.

Conclusion

Serial device servers and industrial gateways are indispensable for bridging communication gaps between legacy equipment and modern digital systems. They enable efficient data exchange, enhance security, and support remote management — all while ensuring cost-effectiveness and scalability.

From manufacturing to healthcare and logistics, these tools empower industries to operate smarter, faster, and more securely in a connected world. As Industry 4.0 continues to evolve, serial device servers and industrial gateways will remain at the heart of intelligent industrial transformation.

Tags : industrial gateway