How Printing Rubber Roller Manufacturers Help Reduce Machine Downtime in Printing Plants

By Sivarollers 13-02-2026 4

In the high-stakes world of industrial printing, time isn’t just money—it is the difference between a profitable quarter and a logistical nightmare. Every minute a printing press sits idle represents lost revenue, wasted labour, and delayed deliveries. While many plant managers focus on motor maintenance or software updates, the secret to peak uptime often lies in a much smaller, yet critical component: the printing rubber roller.

As a leading Printing Rubber Roller Manufacturer in India, Siva Rollers understands that precision engineering is the primary defence against unplanned shutdowns. In this guide, we explore how partnering with the right Printing Rubber Roller Manufacturers can significantly reduce machine downtime and optimise your production cycle.

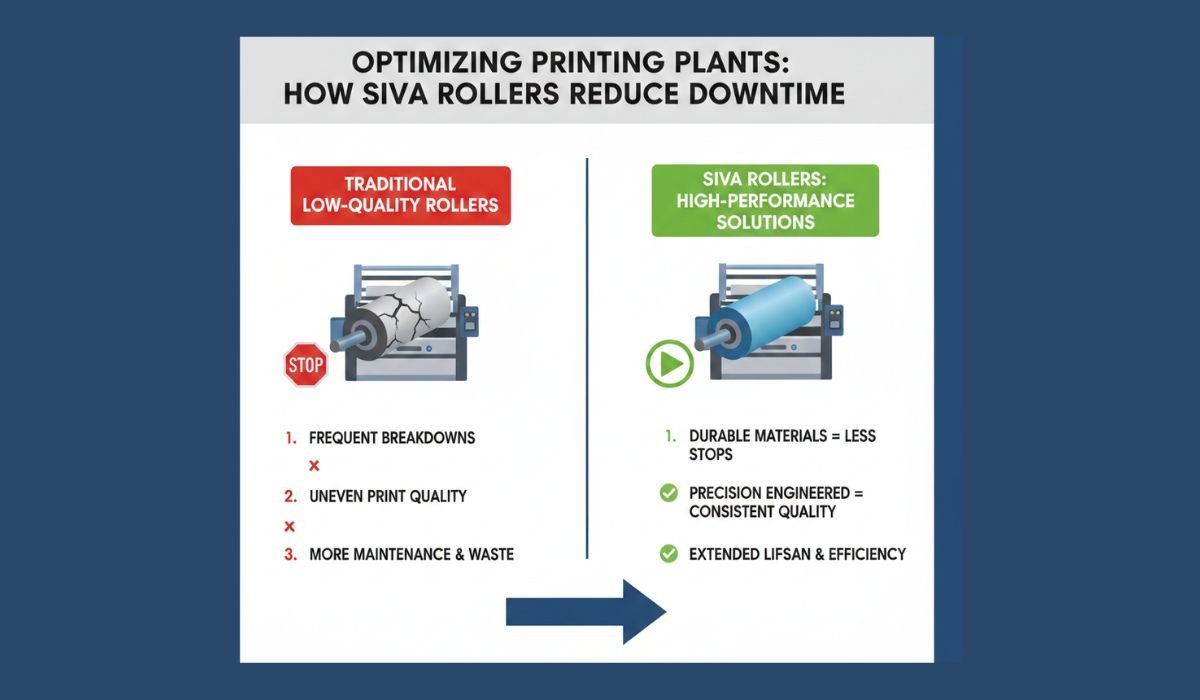

The Hidden Cost of Low-Quality Printing Rollers

Using sub-standard rollers is a classic example of "saving cents to lose dollars." Inferior rubber compounds often fail to withstand the heat, friction, and chemical exposure inherent in high-speed printing.

When a printing roller fails, it doesn't just stop working; it often causes a chain reaction. Poor ink transfer leads to ghosting or smearing, forcing operators to stop the machine for adjustments. Eventually, the rubber might swell, crack, or debond from the core, leading to a complete mechanical halt.

By choosing a reputable Printing Rubber Roller Manufacturer in India, plants ensure that their components are built to endure the rigors of 24/7 industrial operations.

How Expert Manufacturers Minimize Downtime

1. Advanced Material Science and Compound Customization

Not all rubber is created equal. A specialized Printing Rubber Roller Manufacturer develops proprietary compounds designed for specific ink types (UV, solvent, or water-based) and substrates.

Heat Resistance: High-speed presses generate immense friction. Custom compounds prevent the roller from softening or losing its dimensional stability.

Chemical Resilience: Modern inks and cleaning solvents can be corrosive. Industrial-grade rubber ensures the roller surface remains smooth and functional for longer periods.

2. Precision Balancing and Dimensional Accuracy

Vibration is the enemy of the printing press. If a Printing Rubber Roller is even slightly out of balance, it creates uneven wear on bearings and gears.

Siva Rollers, the best Printing Rubber Roller Manufacturer & Supplier in India, utilizes high-precision grinding and dynamic balancing to ensure every roller rotates with perfect concentricity.

This accuracy reduces the need for frequent recalibration, allowing your machines to run faster and longer without manual intervention.

3. Surface Texture and Ink Transfer Efficiency

The "tack" and "finish" of a Printing Rubber Roller in India determine how efficiently ink is transferred from the fountain to the plate.

Correct surface energy prevents ink buildup (piling).

Better ink transfer means fewer stops for "wash-ups," directly increasing your net production hours.

Strategic Maintenance: The Role of the Manufacturer

A transaction doesn't end when a roller is delivered. The best Printing Rubber Roller Manufacturers act as partners in your plant’s success. Reducing downtime is often about prevention rather than reaction.

Professional Re-rubbering Services

Instead of replacing entire metal cores—which is expensive and time-consuming—expert manufacturers offer high-quality re-rubbering. This process involves stripping the old, worn rubber and applying a fresh, precision-engineered layer. This allows plants to maintain a "rotating inventory" of rollers, so a fresh one is always ready to be swapped in during scheduled maintenance.

Troubleshooting Technical Issues

Is your machine experiencing "mottling" or uneven pressure? Often, the issue is environmental. A specialist Rubber Roller Manufacturer in India can analyze your specific plant conditions (humidity, temperature, and speed) to recommend a roller hardness (Durometer) that stabilizes your output.

Why Siva Rollers is the Preferred Partner for Indian Printing Plants

When searching for a reliable Printing Rubber Roller Manufacturer in India, industry leaders look for consistency, durability, and technical support. Siva Rollers has earned its reputation as the Best Printing Rubber Roller Manufacturer & Supplier in India by focusing on three core pillars:

Innovation: We continuously test new synthetic elastomers to provide rollers that outlast standard market offerings.

Quality Control: Every roller undergoes rigorous testing for hardness, diameter tolerance, and surface finish before leaving our facility.

Speed of Service: We recognize that your downtime is a crisis. Our streamlined manufacturing process ensures that replacement rollers reach your plant in record time.

Solving Common Industrial Problems with High-Performance Rollers

Industrial printing plants face several recurring issues that can be solved by upgrading their Printing Rubber Roller quality:

Excessive Heat Buildup: Solved by using heat-dissipating rubber compounds that maintain shore hardness during long runs.

Frequent Swelling: Addressed by using specialized nitrile or EPDM blends that are resistant to the specific oils in your ink.

Edge Wear: Prevented by precision crowning and tapering, ensuring pressure is distributed evenly across the entire web width.

Choosing the Right Printing Rubber Roller in India

Investing in high-quality rollers is a strategic business decision. While the initial cost of a premium Printing Roller from an expert manufacturer may be higher than a generic alternative, the Return on Investment (ROI) is realized through:

Fewer replacement cycles.

Lower energy consumption due to reduced friction.

Higher print quality, leading to fewer customer rejections.

Significant reduction in unplanned machine downtime.

Partner for Productivity

In the competitive landscape of the printing industry, your machinery is only as good as its contact points. The rubber roller is the heart of the printing process. By partnering with a dedicated Rubber Roller Manufacturer in India like Siva Rollers, you aren't just buying a spare part; you are investing in a solution that keeps your presses running at peak performance.

If you are experiencing frequent downtime or inconsistent print quality, it is time to evaluate your rollers. Trust Siva Rollers, the Best Printing Rubber Roller Manufacturer & Supplier in India, to provide the durability and precision your business deserves.

Are you ready to optimize your printing plant? Contact our technical team today to discuss custom roller solutions designed to eliminate downtime and boost your bottom line.