In the world of web processing—whether you are dealing with paper, plastic films, or high-end fabrics—speed is money. The faster your machine runs, the higher your output. But speed is also the enemy of perfection. When webs run fast, they often develop creases, wrinkles, and misalignment issues, leading to costly rejects.

If your plant is struggling with wrinkle removal in textiles or films, and you are constantly slowing down your machinery, the root cause might not be your operator; it might be the quality of your roller technology. The industrial solution trusted globally for decades is the Expander (Bow) Roller. But why does the "OEM-Grade" aspect truly matter, especially when running at peak speed?

The Secret Geometry: Understanding Bowed Rollers

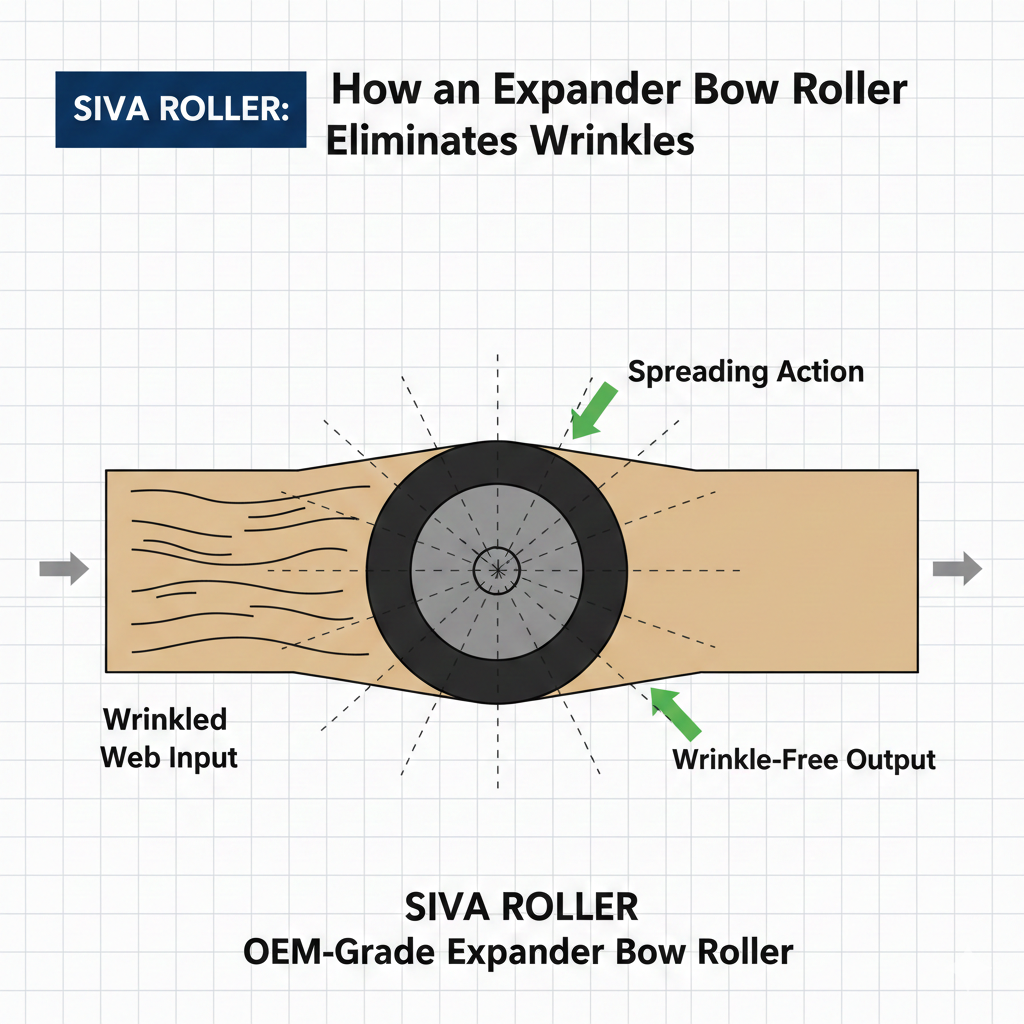

The concept of the Expander Roller is simple yet brilliant. Known also as Bowed Rollers or banana rollers due to their gently curved shape, these are special textile machinery parts designed to spread the material (web) width-wise as it passes over the roller surface.

Unlike a straight idler roll, the Bowed Roller uses a fixed or adjustable center shaft with a curvature. As the web makes contact and wraps around this curved surface, the geometry of the curve forces the material to travel a fractionally longer distance along the outer edges than in the middle. This creates a gentle, consistent spreading action.

This spreading force is the essence of spreader roller technology. It gently pulls the web taut from the center outwards, instantly flattening out any slackness or uneven tension.

Eliminating Wrinkles and Misalignment Issues

The main purpose of installing these components is twofold: to flatten the material and to ensure perfect tracking.

Wrinkle Elimination: The uniform outward pull generated by the roller's curvature effectively smooths out issues like baggy centers or slack edges, which are the primary causes of wrinkles. This makes it an essential component for achieving precise wrinkle removal in textiles before critical processes like printing, coating, or dyeing.

Correcting Alignment: When a web hits a Bowed Roller correctly, it naturally seeks to exit perpendicular (at a 90-degree angle) to the roller’s axis. Since the axis is curved, this forces the web into a perfectly stable path. This capability is critical for solving misalignment issues in web processing, ensuring that the material enters the next stage (like a nip or slitting blade) perfectly straight and flat.

This unique combination of spreading and alignment is why high-quality bowed roller solutions are indispensable in modern, high-speed production environments.

The OEM Difference: Speed, Stability, and Durability

When seeking the best expander roller for wrinkle removal, industrial buyers must look beyond cost and consider the term "OEM-Grade." OEM (Original Equipment Manufacturer) standards ensure precision and reliability that ordinary rollers simply cannot match, especially at high speeds.

A non-OEM or poorly manufactured roller often suffers from:

Vibration and Run-Out: At high RPMs, even a tiny imperfection in the roll's balance or bearing assembly can cause severe vibration. This vibration causes wrinkles, negating the roller's purpose and leading to catastrophic failures.

Poor Industrial Roll Maintenance: High-quality OEM rollers use superior, sealed bearings and durable rubber sleeves (like Ebonite or Nitrile) that resist wear, heat, and chemical exposure, drastically reducing the need for constant maintenance and maximizing uptime.

Inconsistent Bow: The curve must be perfect. If the bow is inconsistent or cheaply built, it can create uneven spreading, causing new wrinkles or damaging the web structure itself.

Choosing an OEM-Grade roller, whether it’s a standard rubber-covered expander or an alternative like a slat expander roller (used typically for highly non-woven or sticky materials), guarantees the precise geometry and robust construction needed to handle the dynamic stresses of high-speed operations.

Siva Roller: Leading Expander Roller Manufacturers in India

When precision and reliability are your top priorities, you need to partner with reliable expander roller manufacturers who understand the rigorous demands of your machinery.

Siva Roller has established itself as a leading Expander Roller manufacturer & supplier in India. Based in the industrial heartland of Ahmedabad, Gujarat, we specialize in producing robust, Ebonite-covered Bowed Rollers and other textile machinery parts designed to meet strict OEM quality standards.

Our manufacturing unit in Ahmedabad focuses on precision balancing, ensuring our rollers achieve high critical speeds without vibration, making them the best expander roller for wrinkle removal for high-speed lines across all industries, from packaging to textiles. We provide comprehensive bowed roller solutions and supply our rollers nationwide, helping businesses throughout India achieve zero-defect production.

Don't let subpar industrial roll maintenance or low-quality components dictate your production speed. Invest in precision.

Ready to Eliminate Wrinkles and Boost Production?

A high-speed line requires rollers that are engineered for stability and durability. By upgrading to a precision-built, OEM-grade Expander (Bow) Roller, you solve the problem of wrinkling and misalignment simultaneously, protecting your material and maximizing your machine’s efficiency.

To discuss your specific material and speed requirements and find the perfect bowed roller solutions for your machinery, contact the experts at Siva Roller today. Let us help you boost your production and minimize wastage.