Digitize embroidery is a critical process in modern embroidery production. It involves converting artwork, logos, or text into a stitch-based digital file that embroidery machines can accurately follow. Without correct digitization, even well-designed artwork may lose its shape, clarity, or balance once stitched on fabric. This makes embroidery digitization essential for achieving clean, consistent, and durable results.

For both commercial embroidery and personal customization, digitizing embroidery ensures precision, repeatability, and efficient production. It serves as the technical link between creative design and reliable machine stitching.

What Does It Mean to Digitize Embroidery?

To digitize embroidery means transforming a standard image file into a structured set of stitching instructions. These instructions guide the embroidery machine on stitch type, stitch direction, stitch density, and stitch sequence. Unlike printing, embroidery depends on thread behavior and fabric response, which makes digitization a specialized skill rather than an automated task.

Although digitizing software is used, professional digitizers manually plan how each element of a design will be stitched. This careful planning helps avoid issues such as fabric puckering, thread breaks, gaps in coverage, or distorted lettering.

A properly digitized embroidery file typically results in:

- Clean outlines with controlled stitch flow

- Balanced stitch density that supports fabric stability

- Smooth transitions between design elements

- Fewer interruptions during machine operation

Why Digitizing Embroidery Is Important

Embroidery machines cannot read regular image formats on their own. They rely entirely on digitized files that translate visual artwork into stitch instructions. Poor digitization can cause uneven stitching, incorrect sizing, and inconsistent results across garments.

Professional digitizing embroidery considers important factors such as fabric type, stitch count, and design scale. These adjustments help maintain embroidery quality even after repeated use and washing. Proper digitization also improves production efficiency by reducing machine errors, downtime, and material waste.

Common Uses of Digitized Embroidery

Digitized embroidery is widely used across many industries and applications. From branding to decorative designs, digitization ensures embroidery remains consistent across different materials and production runs.

Common uses include logos on uniforms, text and monograms for personalization, decorative designs on apparel, and branding on promotional items. Each use case requires a specific digitizing approach to maintain clarity and durability.

Technical Elements That Matter in Embroidery Digitization

The quality of digitized embroidery depends on several technical components that directly affect the final stitched result. These elements are carefully adjusted based on design complexity and fabric behavior.

Key technical factors include stitch type selection, stitch direction for visual consistency, stitch density for proper coverage, and underlay stitching to stabilize the fabric. When these elements are managed correctly, embroidery maintains its shape, structure, and appearance over time.

Benefits of Professional Embroidery Digitization

Using professional services to digitize embroidery offers long-term value for both businesses and individuals. Skilled digitizers combine technical expertise with practical embroidery knowledge, ensuring files perform reliably during production.

The main advantages include accurate stitch placement, compatibility with different embroidery machines, customization based on fabric and size, and fewer production errors. Professional digitization also supports scalable embroidery operations without sacrificing quality.

How the Digitizing Embroidery Process Works

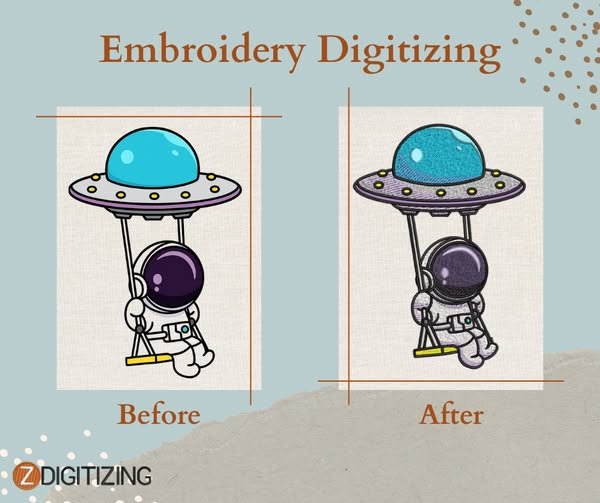

The embroidery digitization process follows a structured workflow. It starts with reviewing the artwork to assess its complexity, color usage, and intended dimensions. The digitizer then manually assigns stitch types, stitch directions, and sequencing using specialized software.

After digitizing, the design is tested through simulation to identify potential issues. Necessary adjustments are made to improve stitch flow, coverage, and stability before delivering the final machine-ready file. This careful process ensures consistent performance during actual embroidery.

Who Needs to Digitize Embroidery?

Digitizing embroidery is essential for embroidery shops, apparel brands, promotional product suppliers, and designers. It is also beneficial for individuals producing custom garments, personalized gifts, or limited production runs.

Anyone seeking dependable embroidery quality can benefit from accurate digitization, regardless of project size.

Choosing a Reliable Digitizing Embroidery Service

Not all digitizing services offer the same level of quality. Choosing a reliable provider plays a major role in the success of embroidery production.

When selecting a service, it is important to review experience, ability to handle detailed designs, revision support, and communication clarity. A dependable digitizing service focuses on embroidery performance rather than relying on automated conversions.

Final Thoughts

Digitize embroidery is more than converting artwork into stitches. It is a technical process that directly affects embroidery quality, durability, and production efficiency. Proper digitization ensures designs stitch accurately, maintain their structure, and perform consistently on fabric.

By investing in professional embroidery digitization, businesses and individuals can achieve dependable results that reflect skill and attention to detail. Accurate digitizing supports efficient production while preserving the integrity of embroidered designs over time.

Tags : Digitize Embroidery