Why Ready Mix Concrete Is a Budget-Friendly Choice for Today’s Construction

By Care RMC 26-12-2025 3

A Shift That Changed the Way We Build

A few years ago, at a mid-sized residential site on the outskirts of a growing city, a familiar problem delayed work again. Raw materials arrived late, labor stood idle, and quality varied from one batch of concrete to another. The site engineer paused and reflected on how construction had changed over the years. Speed, consistency, and accountability were no longer optional. This quiet moment reflects a broader transition across the industry, where Ready Mix Concrete, commonly known as RMC, has become a practical answer to modern construction challenges.

RMC concrete is not just a material choice. It represents a smarter construction mindset that balances cost control with quality assurance. In an era where timelines are tighter and expectations higher, understanding why RMC concrete is cost-effective helps builders, engineers, and planners make informed decisions.

Understanding RMC Concrete in Today’s Context

RMC concrete is produced in a controlled plant setting where every ingredient is measured with precision before being transported directly to the construction site. This organized approach removes many of the uncertainties commonly seen in on-site mixing. In today’s construction landscape, reliability is essential. Project budgets often go off track not because of rising material prices, but due to delays, inconsistent quality, and repeated corrective work.

Centralized production allows RMC concrete to maintain uniform strength and performance across every batch. Each cubic meter meets the same technical standards, which helps structures perform as expected over time. This consistency reduces the risk of early damage and lowers maintenance requirements, resulting in long-term cost savings that are frequently missed during the initial planning stage.

The Real Cost Behind Traditional Site Mixing

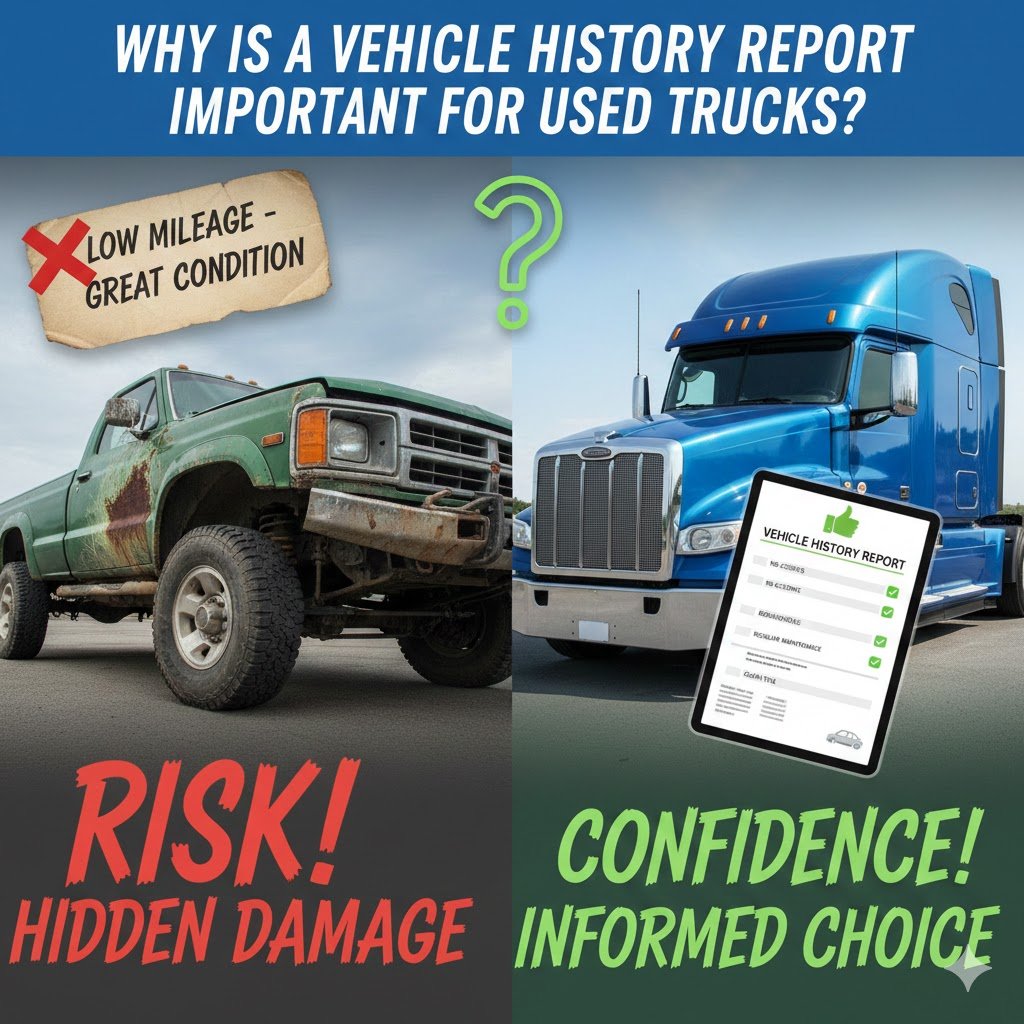

Traditional site mixing may seem economical at first because materials are sourced locally and mixed as needed. However, this method often carries hidden expenses that become noticeable as the project progresses. Improper storage of raw materials, uneven mix proportions, and manual errors can lead to significant material wastage and increased costs.

Dependence on skilled labor further adds to uncertainty, especially when experienced workers are unavailable or inconsistent. Variations in concrete quality can cause surface imperfections, cracks, or reduced strength. These issues rarely appear immediately but emerge later as costly repairs or structural concerns. When viewed from a long-term perspective, site-mixed concrete often proves more expensive, both financially and in terms of durability.

How RMC Concrete Reduces Material Wastage

One of the strongest reasons RMC concrete is cost-effective lies in waste reduction. Plant-controlled batching ensures that materials are used efficiently. Exact quantities are measured, and excess mixing is avoided. This disciplined process minimizes leftover concrete and prevents raw material spoilage.

Over large projects, even small reductions in wastage lead to significant savings. Contractors often notice that sites using RMC maintain cleaner storage areas and better inventory control. This operational clarity supports both cost management and environmental responsibility.

Time Efficiency and Its Direct Impact on Costs

Time, in construction, directly influences money. Delays increase labor expenses, equipment rentals, and overhead costs. RMC concrete accelerates construction by ensuring timely supply and faster placement. There is no waiting for manual mixing or adjusting proportions on-site.

For urban projects, where space and time are limited, RMC deliveries align with scheduled pours. This synchronization keeps workflows smooth. In regions like Uttar Pradesh, many builders now rely on an RMC Plant in Lucknow to meet tight urban project timelines without compromising quality.

Consistent Quality Means Fewer Repairs

Quality consistency is often undervalued during cost comparisons. RMC concrete undergoes regular testing for strength, durability, and workability. These checks ensure compliance with design requirements and local standards.

Structures built with consistent concrete mixes experience fewer early-age defects. Over years of use, this reliability reduces repair and rehabilitation expenses. For infrastructure projects such as pavements, foundations, and commercial floors, this long-term performance significantly improves cost efficiency.

Labor Optimization and Safer Worksites

Modern construction increasingly focuses on safety and skill optimization. RMC concrete reduces dependency on large on-site labor teams required for mixing. Fewer workers handling heavy materials leads to lower accident risks and insurance costs.

Moreover, skilled labor can be redirected toward finishing and quality supervision rather than repetitive mixing tasks. This shift improves overall productivity while maintaining controlled expenditure. As labor costs rise, this advantage becomes even more relevant.

Predictable Budgeting for Large Projects

Budget predictability is a cornerstone of cost-effective construction. RMC concrete offers transparent pricing based on grade, volume, and delivery distance. This clarity helps project managers forecast expenses more accurately.

When sourced from a reliable RMC Concrete Supplier Lucknow, developers benefit from stable supply chains and consistent billing. Predictable costs reduce financial stress and allow better allocation of funds across other critical project areas.

Sustainability as a Cost Advantage

Sustainable construction is no longer a trend but a requirement. RMC plants often incorporate supplementary materials like fly ash, which enhance durability while reducing cement consumption. Lower cement usage not only reduces environmental impact but also lowers material costs.

Efficient transportation planning further reduces fuel consumption. Over time, sustainability-driven efficiencies translate into measurable cost benefits, aligning economic goals with environmental responsibility.

Regional Advantages and Local Expertise

Local production plays a crucial role in cost efficiency. An RMC Plant in Lucknow understands regional climate conditions, soil behavior, and construction practices. This local insight helps in tailoring mix designs that perform better over time.

Similarly, working with an experienced RMC Concrete Supplier Lucknow ensures logistical reliability. Shorter transport distances reduce fuel costs and prevent delays caused by traffic or infrastructure constraints.

Adaptability for Modern Design Needs

Modern architecture demands flexibility. RMC concrete supports customized mix designs for high-rise structures, decorative finishes, and complex formwork. This adaptability reduces trial-and-error costs often associated with site mixing.

As design innovation grows, materials that adapt without compromising cost become invaluable. RMC concrete meets this expectation by blending engineering precision with practical affordability.

Conclusion: Cost-Effectiveness Beyond Numbers

Cost-effectiveness is not just about cheaper materials. It is about smarter systems that reduce risk, save time, and enhance durability. RMC concrete achieves this balance by addressing both visible and hidden costs in construction.

From reducing wastage to improving long-term performance, RMC concrete supports modern construction goals. As projects grow more complex and accountability becomes essential, this approach stands out as a reliable and economical choice.

Frequently Asked Questions

Why is RMC concrete considered more economical over the project lifecycle?

RMC concrete offers long-term savings because it reduces material wastage, ensures consistent quality, and minimizes repair needs. While initial costs may seem comparable, the reduction in labor dependency, faster construction timelines, and improved durability result in lower overall expenses throughout the structure’s lifespan.

Does RMC concrete help in maintaining construction schedules?

Yes, RMC concrete significantly improves schedule adherence. Since it is produced in controlled plants and delivered as per planned timelines, there are fewer interruptions at the site. This reliability helps avoid cascading delays that often increase indirect project costs.

How does RMC concrete improve structural quality?

RMC concrete is produced using precise mix designs and quality checks. This consistency ensures uniform strength and workability across all batches. Better quality control leads to fewer defects, enhanced load-bearing capacity, and improved resistance to environmental factors over time.

Is RMC concrete suitable for both small and large projects?

RMC concrete is versatile and adaptable. It suits residential foundations, commercial buildings, and large infrastructure projects alike. The ability to customize mix designs ensures that even smaller projects benefit from professional-grade quality and cost efficiency.

What role does local sourcing play in RMC cost-effectiveness?

Local sourcing reduces transportation time and fuel costs while ensuring faster delivery. Working with nearby plants also allows mix designs to account for regional climate and soil conditions. This local expertise enhances performance and reduces long-term maintenance expenses.

Tags : RMC Plant in Lucknow