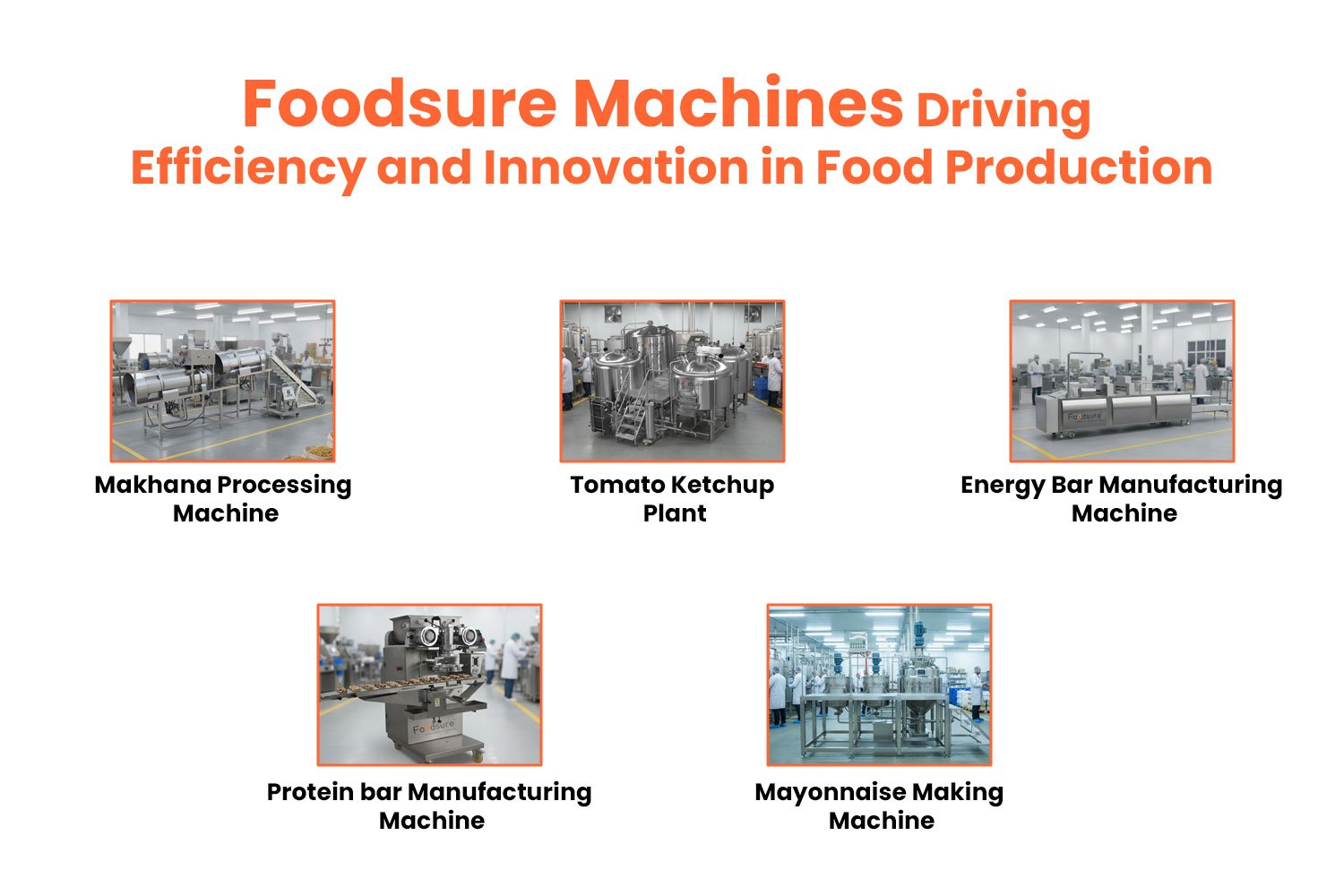

Tomato Puree Processing Plant: What It Is, Why It Matters & How It Works

By Foodsure Machines 31-12-2025 1

The growing demand for tomato-based products has made tomato processing a profitable opportunity for food businesses. From hotels and cloud kitchens to packaged food brands, tomato puree is widely used. To meet quality and volume requirements, manufacturers are turning to a modern tomato puree processing plant.

This guide explains what a tomato puree processing plant is, why it is important, and how the processing works, along with key benefits for food businesses.

What Is a Tomato Puree Processing Plant?

A tomato puree processing plant is a complete production system used to convert fresh tomatoes into smooth, thick, and shelf-stable tomato puree. The plant includes washing, sorting, pulping, heating, concentration, and packaging units.

Unlike traditional manual methods, an automatic tomato puree processing plant ensures uniform texture, consistent taste, and better hygiene. These plants are suitable for small, medium, and large-scale food manufacturers and can also be used for tomato paste and sauce production.

Why Is a Tomato Puree Processing Plant Important for Food Businesses?

Investing in a tomato puree processing plant helps businesses maintain product quality while reducing operational costs. Manual processing often leads to high wastage, uneven batches, and contamination risks.

A modern industrial tomato processing plant improves efficiency by minimizing raw material loss and increasing yield. It also ensures compliance with food safety standards, which is essential for supplying to large buyers and export markets.

Another major reason is scalability. A well-designed tomato puree manufacturing unit can be upgraded as demand increases, making it a long-term investment for growing food brands.

How Does a Tomato Puree Processing Plant Work?

The working process of a tomato puree processing plant is systematic and controlled:

Step 1: Washing and Sorting

Fresh tomatoes are thoroughly washed to remove dirt and impurities. Damaged or unripe tomatoes are removed during sorting.

Step 2: Crushing and Pulping

Clean tomatoes are crushed and passed through pulpers that separate seeds and skin, producing smooth tomato pulp.

Step 3: Heating and Concentration

The pulp is gently heated to achieve the desired thickness and improve shelf life. Temperature control helps retain color and flavor.

Step 4: Packaging

The final tomato puree is packed using hygienic or aseptic packaging systems to ensure long storage without preservatives.

How Does an Automatic Tomato Puree Processing Plant Reduce Costs?

An automatic tomato puree processing plant reduces labor dependency, processing time, and energy consumption. Efficient machines ensure low tomato wastage and higher output per batch.

Automation also minimizes human error, which helps maintain batch-to-batch consistency. Over time, this results in lower production costs and improved profit margins.

Why Is This Plant a Smart Investment for Startups and Large Units?

For startups, a tomato puree processing plant provides a strong foundation with scalable capacity. For established manufacturers, it helps meet bulk demand while maintaining quality.

With increasing demand for packaged foods and ready-to-use ingredients, tomato puree manufacturing offers stable returns and long-term growth opportunities.

FAQs – Tomato Puree Processing Plant

1. What capacity options are available for a tomato puree processing plant?

Tomato puree processing plants are available in small, medium, and large capacities. The capacity can be selected based on daily tomato intake and production goals.

2. Can the same plant be used for tomato paste production?

Yes, most tomato puree processing plants can be configured for tomato paste by increasing the concentration level.

3. Is an automatic tomato puree processing plant suitable for startups?

Yes, automatic plants are suitable for startups because they offer consistent quality, lower wastage, and easy scalability.

4. How much raw material loss occurs during tomato processing?

With modern tomato processing plants, raw material loss is minimal due to efficient pulping and refining systems.

5. Does a tomato puree processing plant require high maintenance?

No, most modern plants are designed for easy cleaning and low maintenance, especially those with food-grade and automated components.

Tags : .....