The Ultimate Guide to Fall Protection: Anatomy of the Modern Safety Belt Full Body

By Karan Sharma 29-01-2026 2

Working at height is inherent to many vital industries, from construction and telecommunications to maintenance and mining. While essential, these tasks carry the significant and constant risk of a fall. The cornerstone of mitigating this hazard is the Personal Fall Arrest System (PFAS), and the most critical component of that system is the safety belt full body harness. Far surpassing the limited capabilities of waist belts, the modern full body harness is engineered not just to stop a fall, but to manage the subsequent forces and keep the wearer safely suspended in an upright position until rescue. This piece of equipment is the ultimate life-saving interface between the worker and the anchorage point. Understanding its design, function, and correct use is paramount to ensuring worker security and regulatory compliance on every job.

The Anatomy of Assurance: Components of a Full Body Harness

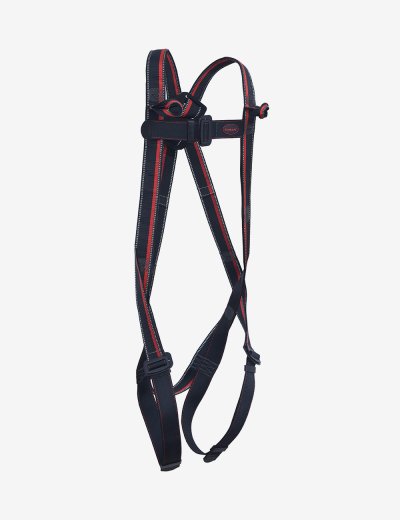

A premium safety belt full body harness is a complex assembly of engineered materials designed to distribute the immense forces generated during a fall arrest across the stronger parts of the body, such as the pelvis, chest, and thighs.

Key components that define its efficacy include:

Webbing: Typically constructed from high-strength polyester or nylon, the webbing forms the adjustable straps that wrap around the user. It must be durable, UV-resistant, and possess a certified minimum tensile strength capable of withstanding the dynamic load of a stopped fall.

D-Rings (Attachment Elements): These forged metal rings are the connection points for lanyards, lifelines, or other connecting devices. The most critical is the Dorsal D-Ring, positioned between the shoulder blades, which is the primary attachment point for fall arrest systems (conforming to standards like EN 361). Other vital rings include Sternal D-Rings for descent or ladder climbing systems, and Lateral D-Rings (side D-rings), typically used for work positioning.

Buckles and Adjusters: These metal fittings allow the harness to be custom-fitted to the individual worker. Quick-connect or tongue-buckle systems ensure secure locking, while adjusters on the shoulder, chest, and thigh straps are essential for a snug, non-slip fit that prevents the harness from moving during a fall or prolonged use.

Proper inspection of these elements, checking for corrosion on metal fittings, fraying webbing, and intact stitching patterns, is mandatory before every single use.

Beyond Fall Arrest: Specialised Functions and Harness Classes

The versatile design of the safety belt full body harness means it can be adapted for multiple working scenarios, each requiring different attachment and structural features, often categorised by their function:

Fall Arrest (Class A): The fundamental purpose. Utilises the dorsal or sternal D-ring to connect to a shock-absorbing lanyard, stopping a free fall and distributing forces.

Work Positioning (Class P): Required for professionals who need to lean back and work hands-free (e.g., rebar work, tower climbing). This necessitates a waist belt with two Lateral D-Rings (side D-rings), which must be used in conjunction with a separate fall arrest system. Compliance with standards like EN 358 ensures the harness can support the user's weight comfortably during work.

Rope Access/Sit Harness (Class C/E): Used by professionals involved in controlled ascent, descent, and rescue operations. These harnesses often feature a Ventral D-Ring (front-waist/pelvic) attachment point (conforming to EN 813 standards) to safely manage the worker's centre of gravity during suspension.

Confined Space Entry and Rescue (Class E): These incorporate shoulder-mounted D-rings or loops to allow workers to be safely raised or lowered vertically into or out of confined spaces, maintaining an upright posture throughout the retrieval process.

Selecting the appropriate class of harness, in line with the job's specific risk profile, is crucial for both safety and ergonomic efficiency.

Ergonomics and Compliance for Extended Use

While safety is the priority, worker comfort is essential for compliance. An uncomfortable harness will be adjusted incorrectly or avoided altogether, rendering the protection useless. Modern harnesses are designed with advanced ergonomics for extended use:

Padded Straps: Padding at the shoulder, thigh, and sometimes waist level, often backed with breathable mesh, reduces pressure points and minimises fatigue, especially when a worker is suspended or subjected to the weight of their tools.

Fit and Adjustment: Features like quick-release leg and chest buckles, and dedicated strap keepers, ensure the harness can be easily donned, adjusted, and secured. Correct fitting is vital; straps should be snug but allow for freedom of movement without rubbing or causing chafing.

Corrosion Resistance: All metallic components, including D-rings and buckles, are typically treated with coatings (such as CED) to ensure superior resistance against corrosion from moisture, sweat, and environmental factors, guaranteeing the harness retains its structural integrity over its service life.

Adherence to globally recognised standards, coupled with rigorous pre-use inspection and an understanding of the working environment, defines a mature safety culture. The reliability of the safety belt full body harness is directly linked to its design quality and the wearer's commitment to correct usage and maintenance.

The full body harness represents the peak of fall protection technology, serving as the most vital line of defence for any individual working at elevation. It is a meticulously engineered system designed to turn a catastrophic accident into a survivable incident. Investing in certified, multi-functional, and ergonomically superior harnesses is not merely meeting a regulation; it is making a profound commitment to human safety. Always ensure that the safety belt full body harness used matches the specific application and that all users are fully trained in its fitting, inspection, and the corresponding fall protection system.