Wearable Product Development: the Future of Smart Living.

The world is changing at a fast rate and wearable technology is one of the most revolutionary inventions of this decade. Since smartwatches, fitness trackers, health-monitoring bands, and other industrial devices are in demand, the production of intelligent and portable gadgets is becoming more popular than ever. With the increase in consumer expectations, firms are in search of sound Wearable product development methods that will assure innovation, reliability and market success.

It does not matter whether you are a startup that is planning to launch your first wearable device or an established brand that wants to add to your portfolio, it is crucial to understand the entire process of end-to-end development. This guide will provide all the information you require to know including idea validation, production, and how to figure out all the hardware, software, and user experience design.

What Is Wearable Product Development?

Wearable product development is a comprehensive process related to designing, engineering, prototyping, testing and production of wearable products that become part and parcel of the life of the user. These systems are usually fitted with sensors, microcontrollers, connection modules, and software, which trace, communicate, or guide users in real-time.

Examples include:

Smartwatches

Fitness & health trackers

Smart clothing

AR/VR glasses

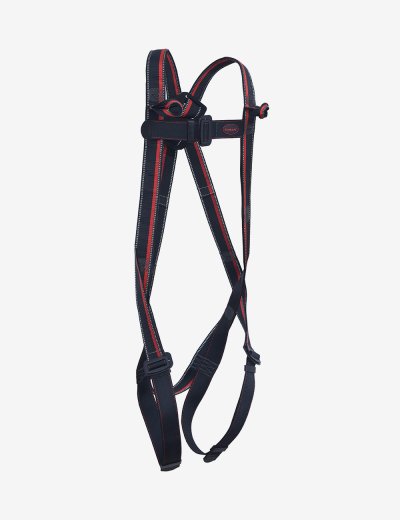

Safety industrial wearables.

Medical quality surveillance equipment.

IoT-enabled wearables

Every category has a blend of engineering, ergonomic design, smooth integration of apps, and durability that needs to be long term.

The reason Wearable Technology is a Boom.

The wearable tech market is growing fast all over the world because of:

1. Health & Fitness Trends

There is a growing interest in tracking the heart rate, stress, sleep, and daily activity of people and this leads to an increase in the demand on sophisticated wearable opportunities.

2. IoT Integration

As IoT is now a regular event, wearables are now linked to smart homes, healthcare and industries.

3. Enterprise Applications

Business owners exploit wearables in the safety of employees, real-time data collection, as well as enhanced efficiency at work.

4. Medical Advancements

Wearables are improving patient supervision, prompt diagnosis and distant medical treatment.

5. Lifestyle Convenience

Wearables will have a seamless connection, hand-free communication and customized experiences.

Important Wearable Product Development Stages

A successful wearable needs skills in the field of electronics, design, software, and user experience. The significant phases are as follows:

1. Concept & Market Research

Prior to the design, before rolling it out, it is important to understand the target audience. This includes:

Competitor analysis

Pain point identification by the users.

Evaluating market gaps

Product feasibility studies.

This is aimed at testing the concept and making the wearable relevant and competitive.

2. Ergonomics and Industrial Design.

Wearable has to be small, light, comfortable and stylish. Designers focus on:

Form factor design

Optimization of size and weight.

Material selection

Long-term wearability.

Wearables are very mundane thus aesthetics and ergonomics is as relevant as technology.

3. Hardware Development

This contributes to the foundation of any wearable. Hardware engineers develop:

Sensor configurations

Microcontroller boards

Battery systems

Bluetooth/Wi-Fi modules

PCB design

Power management systems

The effective design of hardware guarantees the durability, accuracy and optimum functioning.

4. Firmware and Software Development.

Wearables are very dependent on smooth integration of software. The development includes:

Gadgets software.

Mobile apps (Android/iOS)

Data visualization web dashboards.

Cloud platform integration

Data safety security measures.

The experience should be easy in device, application, and the cloud.

5. Prototyping & Testing

The prototyping is used to establish the design before mass-producing. Testing includes:

Functional testing

Durability & stress testing

Battery performance

Connectivity tests

Sensor accuracy validation

User experience trials

Several tests could be conducted in order to perfect the product.

6. Certifications & Compliance

Wearable devices should conform to the world safety and performance standards including:

CE

FCC

RoHS

ISO

Healthcare wearable medical certifications.

Through certification, there is legal acceptance and market acceptance.

7. Manufacturing & Scale-Up

Once the design has been finalized and all tests have been passed, the wearable enters:

Mass production

Quality control

Supply chain optimization

Packaging design

The presence of a trusted partner in the manufacturing industry is crucial to deliver uniformly and in good timing.

Recent Trends that influence the development of wearable products

1. AI-Powered Wearables

Intelligent software increases real-time tracking, forecasts, and individualization.

2. Flexible & Soft Electronics

Wearables are more comfortable and fashionable due to the thin and flexible materials.

3. Sustainable Materials

Straps, casings, and packaging are also being made of materials that are eco-friendly.

4. Medical-Grade Sensors

The remote patient care is changing with advanced biosensors.

5. AR & VR Wearables

AR devices are redesigning training, gaming, and business processes.

The importance of a Professional Wearable Product Development Partner

The creation of a wearable device is not an easy task as it is difficult to combine hardware, firmware, UI/UX, cloud platform, and ergonomic design. A professional development company ensures:

Reduced development risks

Faster time to market

Precision engineering

Optimized performance

Adherence to international standards.

Economical cost manufacturing solutions.

By having a competent partner, brands can transform ideas into something novel in the form of a wearable product users are fond of.

Wearable Product Development Frequently Asked Questions.

1. What is the duration of the wearable product development?

Complexity length may require 6 to 18 months, which involves design, prototyping, testing, and certifications.

2. How much does it cost to come up with a wearable?

Prices differ according to functionality, sensors, connectivity and design. Simple wearables can be cheaper, and more sophisticated medical-based solutions would cost more.

3. Which sensors are most typically used in wearables?

Popular sensors include:

Heart rate monitors

Accelerometers

Gyroscopes

SpO2 sensors

Temperature sensors

GPS modules

4. Is it possible to connect wearables and mobile applications and cloud services?

Yes. Contemporary wearables are based on cloud dashboards and data storage using apps and visualization.

5. Do wearables need certifications?

Absolutely. Such certifications as CE, FCC and RoHS provide the safety, quality and sale permission in the world markets.

6. Are startups able to create wearable devices?

Yes! A number of established wearable brands began as startups. Even a new business can introduce new wearable products with the help of the appropriate development partner.

Final Thoughts

The next step of smart living, health-related tracking, and flawless online connectivity is wearable technology. The wearable product can become a competitive product in the market with the correct strategy, engineering knowledge, and customer-oriented design. The process of developing wearable products is a successful process, and the reliability, innovation and scalability are guaranteed through a properly organized process of developing wearable products- transforming the visionary ideas into the world-class wearable devices.

Tags : wearable product development