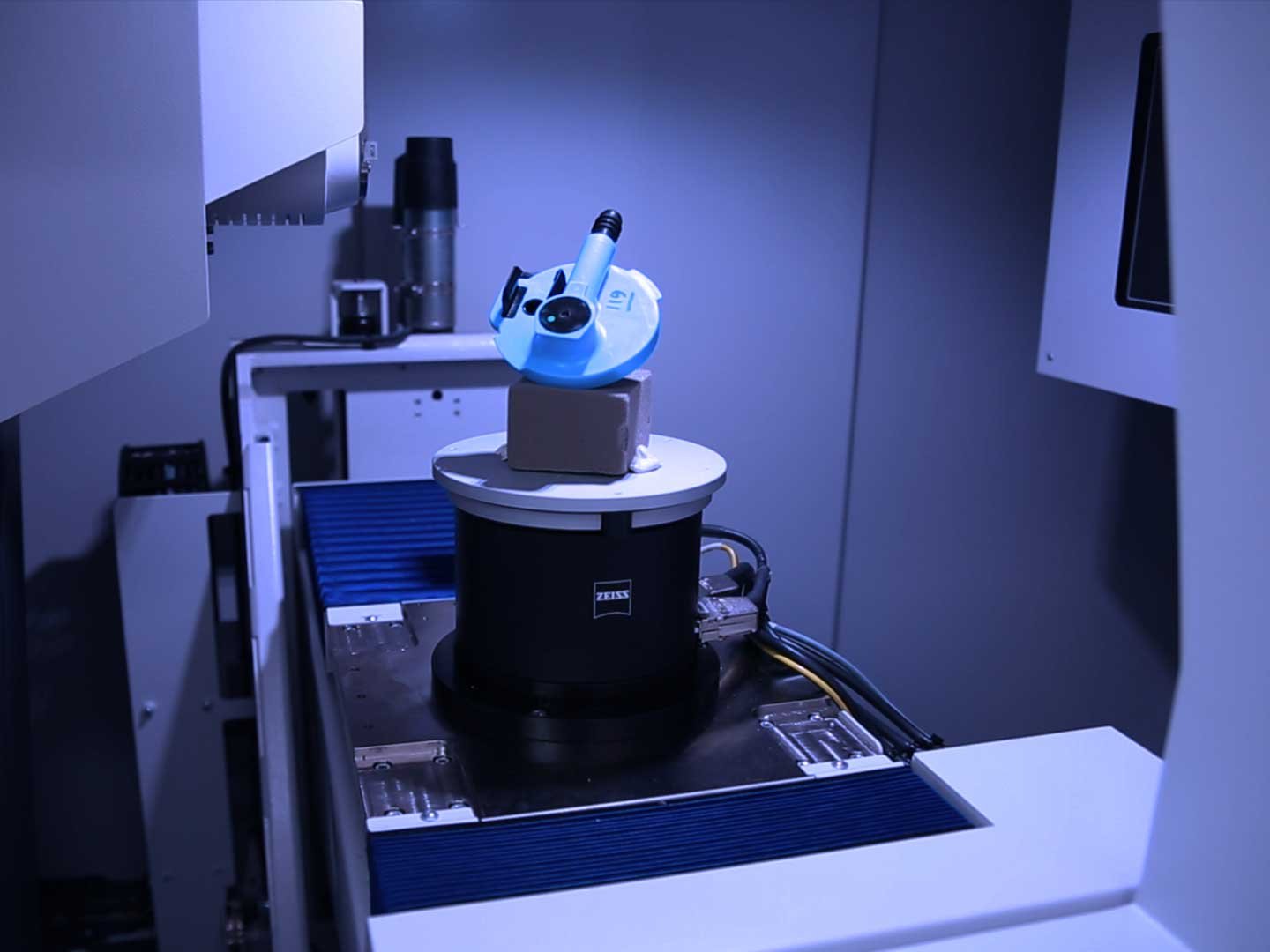

Industrial CT scanning has become one of the most advanced inspection technologies in modern manufacturing. Its ability to see inside components without destroying them makes it invaluable for quality control, reverse engineering, and failure analysis. However, one of the most common questions manufacturers ask is: how accurate is industrial CT scanning, and what tolerances can it reliably achieve?

This article explains industrial CT scanning accuracy in simple terms, covering achievable tolerances, influencing factors, and real-world capabilities across industries.

What Is Industrial CT Scanning?

Industrial CT scanning (Computed Tomography) uses X-rays to capture thousands of internal images of a component from multiple angles. These images are reconstructed into a detailed 3D model, allowing engineers to inspect both internal and external features without cutting the part open.

Unlike traditional inspection methods, industrial CT scanning enables:

Internal defect detection

Wall thickness analysis

Dimensional measurement

Assembly inspection

Material integrity analysis

How Accurate Is Industrial CT Scanning?

The accuracy of industrial CT scanning depends on several factors, but modern systems are capable of delivering high-precision measurements, often within micron-level tolerances for small and medium-sized components.

Typical Accuracy Ranges

While results vary by application, common achievable accuracy ranges include:

±5–20 microns for small, high-resolution scans

±20–50 microns for medium-sized industrial components

±50–100 microns for large or dense parts

These tolerances make industrial CT scanning suitable for many dimensional inspection tasks traditionally handled by CMMs, especially where internal geometry is involved.

Key Factors That Influence Accuracy

1. Component Size and Geometry

Smaller parts generally achieve higher accuracy because they can be scanned at higher resolution. Larger components require wider scan volumes, which can slightly reduce precision.

Complex shapes, thin walls, and deep internal features may also affect measurement certainty.

2. Material Type and Density

Material composition plays a major role in industrial CT scanning accuracy:

Plastics and composites offer excellent scan clarity and high accuracy

Aluminium and light metals scan well with strong dimensional reliability

Dense metals (steel, titanium) may require advanced settings and longer scan times

Higher-density materials can introduce artefacts that must be corrected during analysis.

3. Voxel Size (Resolution)

Voxel size is the CT equivalent of pixel size. Smaller voxels result in higher resolution and better accuracy.

For example:

A 10 µm voxel size allows extremely fine feature detection

Larger voxels reduce resolution but enable scanning of bigger parts

Choosing the correct voxel size is critical for achieving reliable tolerances.

4. System Calibration and Environment

Accurate industrial CT scanning relies on:

Regular machine calibration

Temperature-controlled environments

Stable component positioning

Professional metrology-grade CT systems are calibrated using traceable standards to ensure consistent accuracy.

Industrial CT Scanning vs Traditional Measurement Methods

CT Scanning vs CMM

| Feature | Industrial CT Scanning | CMM |

|---|---|---|

| Internal features | ✅ Yes | ❌ No |

| Non-destructive | ✅ Yes | ✅ Yes |

| Complex geometry | ✅ Excellent | ⚠ Limited |

| Speed for assemblies | ✅ Fast | ❌ Slower |

| Highest surface accuracy | ⚠ Slightly lower | ✅ Higher |

While CMMs still offer superior surface accuracy in some cases, industrial CT scanning provides unmatched insight into internal tolerances and assembled parts.

What Can Industrial CT Scanning Measure Accurately?

Industrial CT scanning is highly capable across a wide range of inspection tasks:

Dimensional Measurement

Hole positions

Wall thickness

Internal channels

Thread profiles

Defect Detection

Porosity

Cracks

Inclusions

Voids

Assembly Inspection

Component alignment

Internal fit and clearance

Hidden damage

Reverse Engineering

Full 3D geometry capture

CAD model generation

Tolerances: What’s Realistic in Production?

Industrial CT scanning is ideal for verification, validation, and investigation, rather than ultra-tight surface-only tolerance control.

Best-fit use cases include:

Injection-moulded components

Additive manufacturing

Castings

Complex assemblies

Safety-critical parts

For extremely tight tolerances (below ±5 microns on external surfaces), CT scanning is often combined with CMM or optical inspection for best results.

Advantages of Industrial CT Scanning Accuracy

Measures features that cannot be accessed physically

Reduces destructive testing costs

Detects defects before failure occurs

Supports faster root-cause analysis

Improves confidence in quality assurance

Limitations to Be Aware Of

While powerful, industrial CT scanning is not always the right tool:

Very large parts may exceed scanner capacity

Extremely dense materials can reduce clarity

Surface-only ultra-precision may favour contact methods

Understanding these limitations ensures the right inspection method is selected.

Conclusion

Industrial CT scanning accuracy has advanced significantly, making it a trusted inspection solution across manufacturing, aerospace, automotive, and medical industries. With achievable tolerances down to a few microns in the right conditions, it offers unmatched insight into internal structures and complex geometries.

When used correctly, industrial CT scanning delivers accurate, repeatable results that improve quality, reduce risk, and support smarter engineering decisions.

Tags : Industrial CT Scanning