In every industrial process—whether it’s printing, packaging, textile, paper, or converting—the Rubber Coated Roller plays a vital role in ensuring smooth, precise, and efficient operation. Selecting the right roller isn’t just about choosing a part; it’s about optimizing performance, durability, and consistency in your production line. The wrong choice can lead to machine downtime, uneven material handling, and costly replacements. Let’s explore how you can choose the perfect Rubber Coated Roller for your specific application and why working with a trusted manufacturer makes all the difference.

Understanding the Role of a Rubber Coated Roller

A Rubber Roller is a core component designed to grip, feed, or press materials in various industrial machines. The coating material—usually natural or synthetic rubber—provides the necessary friction, wear resistance, and resilience for smooth operation. In Rubber Roller India applications, rollers are customized for different machine types such as offset printing presses, laminators, textile calendars, and paper mills. The right rubber compound ensures resistance to chemicals, temperature variations, and mechanical stress.

Key Factors to Consider Before Choosing

Every industry has its unique operating conditions. To select the ideal Rubber Coated Roller, consider these critical aspects that directly affect performance and service life.

1. Application Type and Function

Identify what the roller will be used for—coating, feeding, printing, or pressing. Each function demands different hardness levels and surface finishes. For example, printing rollers require high precision and excellent surface uniformity, while textile rollers need elasticity to handle delicate fabrics without damage.

2. Rubber Material and Hardness

The coating material is crucial. EPDM rubber offers resistance to heat and ozone, Nitrile rubber (NBR) resists oils and solvents, while Silicone rubber withstands extreme temperatures. The Shore hardness (measured on a durometer) determines how soft or firm the roller feels. Softer rollers absorb vibration and grip materials better, while harder ones ensure accurate alignment and dimensional stability.

3. Operating Environment

Temperature, humidity, and exposure to chemicals affect roller performance. A Rubber Roller Manufacturer in India will tailor the coating to suit your working conditions—whether it’s a high-heat packaging line or a solvent-based printing system.

4. Core Material and Balancing

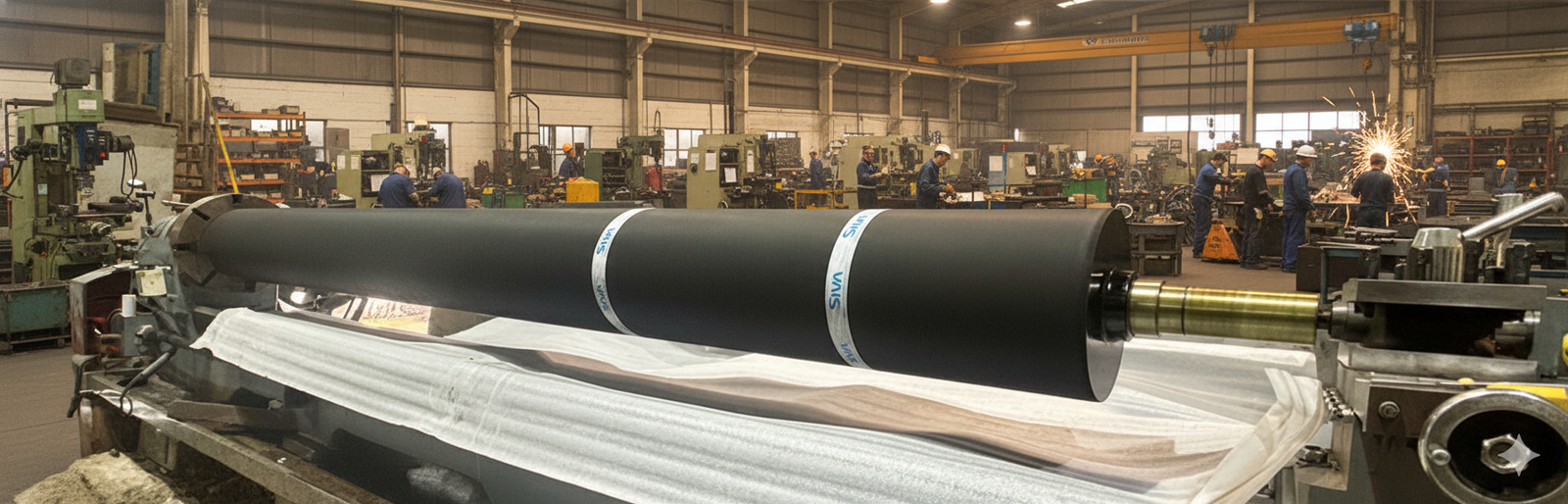

The roller core, often made from steel or aluminum, must be precisely balanced to avoid vibration and ensure uniform pressure distribution. A poorly balanced core causes wear and affects product quality. Manufacturers like Siva Rollers, known as the Best Rubber Coated Roller Manufacturer, Supplier & Exporter, use advanced dynamic balancing techniques to achieve long-term stability.

5. Surface Finish and Coating Quality

The surface finish determines how materials interact with the roller. Glossy finishes reduce friction, while matte finishes increase grip. Uniform coating thickness is essential for consistent performance, and advanced manufacturing ensures zero imperfections or air pockets.

The Importance of Customization

Every industry has unique requirements, and customization is often the key to achieving efficiency. A reliable Rubber Coated Roller Manufacturer will offer tailored solutions—selecting the right rubber compound, surface treatment, and core design. Whether you’re handling high-speed film lamination or precision paper calendaring, customization ensures optimal roller life and flawless output.

Durability and Maintenance Considerations

Even the best rollers require periodic maintenance. Regular cleaning with suitable solvents prevents chemical buildup, while timely recoating extends service life. The overall rubber roller price depends not just on size or coating type, but also on quality standards, precision machining, and after-sales support. Instead of focusing only on initial cost, consider the total lifecycle value—high-quality rollers minimize downtime and reduce long-term expenses.

Why Choose Siva Rollers

Siva Rollers stands out as one of India’s most trusted names in the industry. With decades of experience, they specialize in manufacturing and exporting Rubber Coated Rollers that meet international quality benchmarks. From designing custom compounds to precision machining and dynamic balancing, every roller is crafted to deliver superior performance and consistency. Their expertise as a Rubber Roller Manufacturer in India ensures that each product is tested for hardness, adhesion, and concentric accuracy—making them the preferred choice for industrial clients worldwide.

Conclusion

Choosing the perfect Rubber Coated Roller means understanding your application, environment, and performance needs. Factors like material type, hardness, core balance, and surface finish determine how well your machines will perform over time. Partnering with a trusted Rubber Roller Manufacturer like Siva Rollers guarantees precision-engineered solutions that enhance efficiency, reduce maintenance costs, and extend machine life.

When quality, reliability, and performance matter most, Siva Rollers delivers the ideal Rubber Coated Roller for every industrial application—proving why they remain a leader in Rubber Roller India manufacturing and global supply.